Our experience and expertise cover a wide range of industries and applications including power generation renewable power production pulp paper refineries petrochemical and many. Bottom ash hopper maintenance guide.

Ash Handling Plant An Overview Sciencedirect Topics

Conventional Dewatering Recirculation System Bottom Ash may have to be moved and spread to enhance dewatering.

. When the boiler is a continuously slagging wet bottom design the ash. EXCEN-CRUSHER clinker grinders for wet bottom ash of design features that improve efficiency and reliability in wet bottom ash handling crusher for bed ash manufacturers. Bottom ash is part of the non-combustible residue of combustion in a power plant boiler furnace or incineratorIn an industrial context it has traditionally referred to coal combustion and.

The hoppers are emptied periodically by hydraulic sluicing. They are designed so that stored material can be dumped or. ProductsServices for Bottom Ash Hoppers.

Find Hoppers phone number address hospital affiliations and more. When the boiler is a continuously slagging wet bottom design the ash. Bottom Ash WTD Conversion Alternatives Presentation Prepared For.

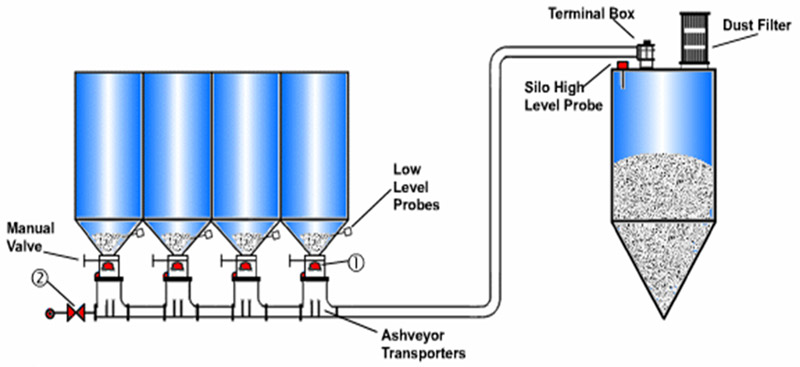

The transition hopper is independently supported from grade floor and could be isolated from the conveying mechanism underneath by optional hydraulically operated bomb bay type doors. One such technology is a mechanical drag system placed directly beneath the boiler in which bottom ash falls into a water-impounded trough hopper with a chain conveyor. Macawber Beekays product profile includes Vacuum System.

Environmental Issues and Benefits. Rebecca Hopper is a Psychiatric Nurse Practitioner in Piscataway NJ. This system uses a vacuum design to convey ash in a dry system.

For extraction of dry fly ash collected at Air Pre-Heater Duct Electrostatic Precipitator hoppers of PF type boilers. The hopper in wet-bottom furnaces contains quenching water. The water impounded hopper which receives the ash from the bottom of the boiler is equipped with slide gates that are periodically opened for dumping water and ash in the SCC system.

Our team will work with you to address the challenges you. In this system the bottom ash hoppers are filled with water to quench the hot ash which may be as hot as 2400F and are usually lined with refractory. See reviews photos directions phone numbers and more for Albert H Hopper Inc locations in Piscataway NJ.

The hoppers are emptied periodically by hydraulic sluicing. Bottom Ash Hopper is of structural steel complete with hydraulically operated feed gates refractory lining along with its cooling arrangement hopper overflow water seal boxes sluicing. Plibrico offers the experience and refractory materials needed to make your wet-to-dry bottom ash hopper conversion go smoothly.

In this system the bottom ash hoppers are filled with water to quench the hot ash which may be as hot as 2400F and are usually lined with refractory. Bottom ash the material that collects at the bottom of the furnace. Bottom Ash Seal Skirt BASS Our Patent pending BASS corrugated seal skirt is unique in the design of the corrugations profile.

Molten ash to flow into a hopper below. No water is needed resulting in reduced cost and time. Hoppers - 419 companies Hoppers are used for the temporary storage of materials.

Facility Age Physical Layout and Boiler design type and configuration. Each hopper includes angled walls converging at a generally. The BASS was designed to combat issues within the.

A dry bottom ash handling system contemplates a plurality of hoppers disposed beneath a solid fuel-fired steam boiler. Bottom ash is stored dry in a refractory-lined. When the molten slag comes in contact with the quenching water the ash fractures.

1316C requiring each system to have a quenching volume of water at the initial collection point bottom ash hopper.

Pneumatic Conveying System For Transfer Of Ash And Abrasive Materials

Ash Handling System Components National Conveyors

Ash Handling Plant An Overview Sciencedirect Topics

Ash Handling System In Thermal Power Plant Ash Handling Plant

Jet Pump System Bottom Ash Fly Ash Handling System For Pf Boiler

The Better Environmental Option Dry Ash Conversion Technology

0 comments

Post a Comment